If you’re looking for an efficient and cost-effective feeding solution for your livestock, precast concrete feed bunks are the answer. Available in fenceline style Cattle and Sheep feedbunks these bunks are convenient to use and easy to maintain. Here are the benefits you can look forward to when adding them to your property.

Why You Should Choose Precast Concrete feed bunks

1. Keeps Feed Clean & Accessible

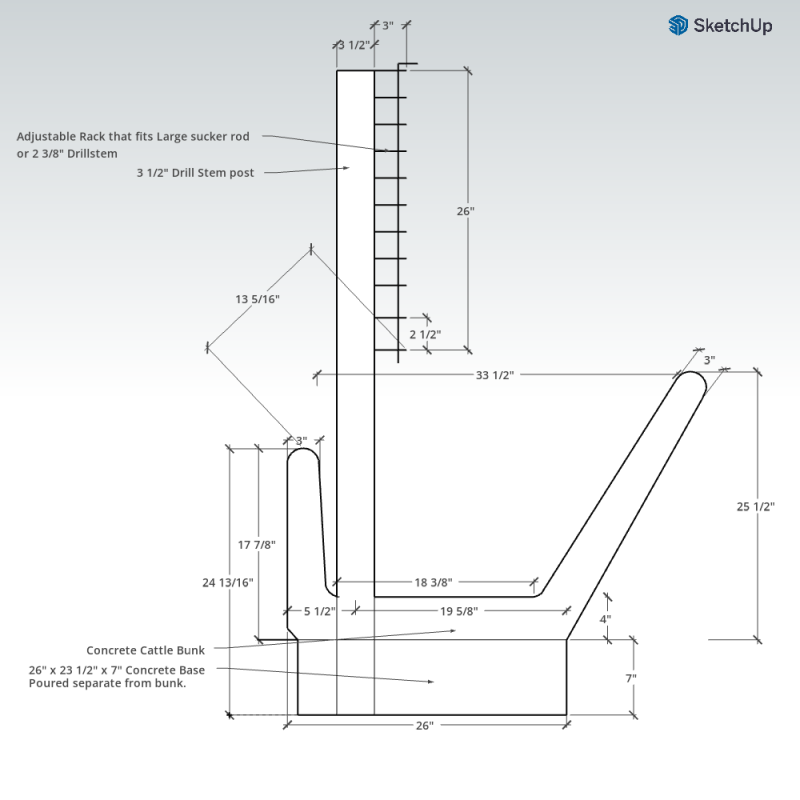

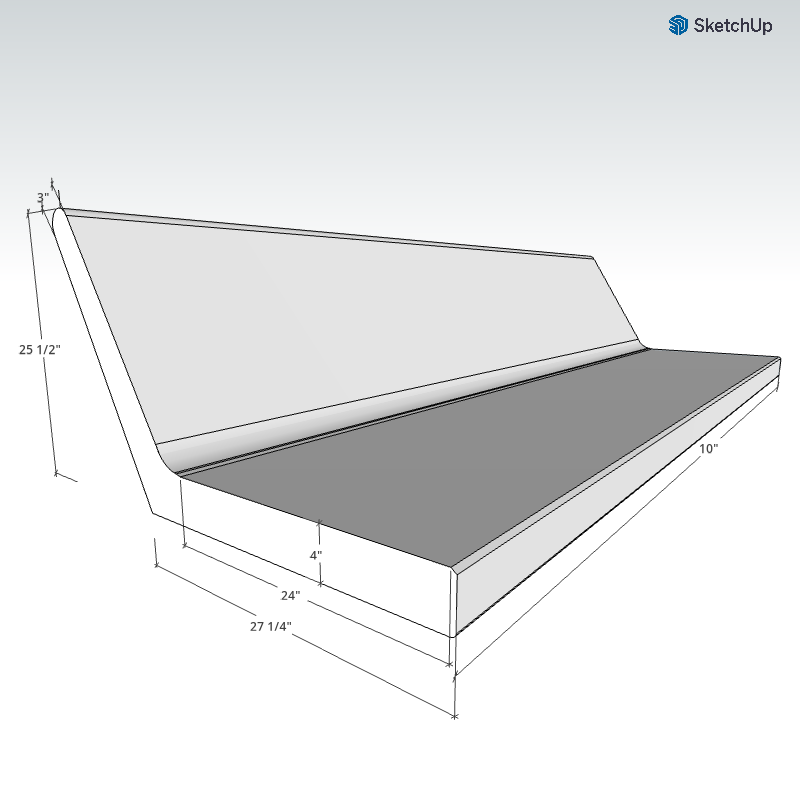

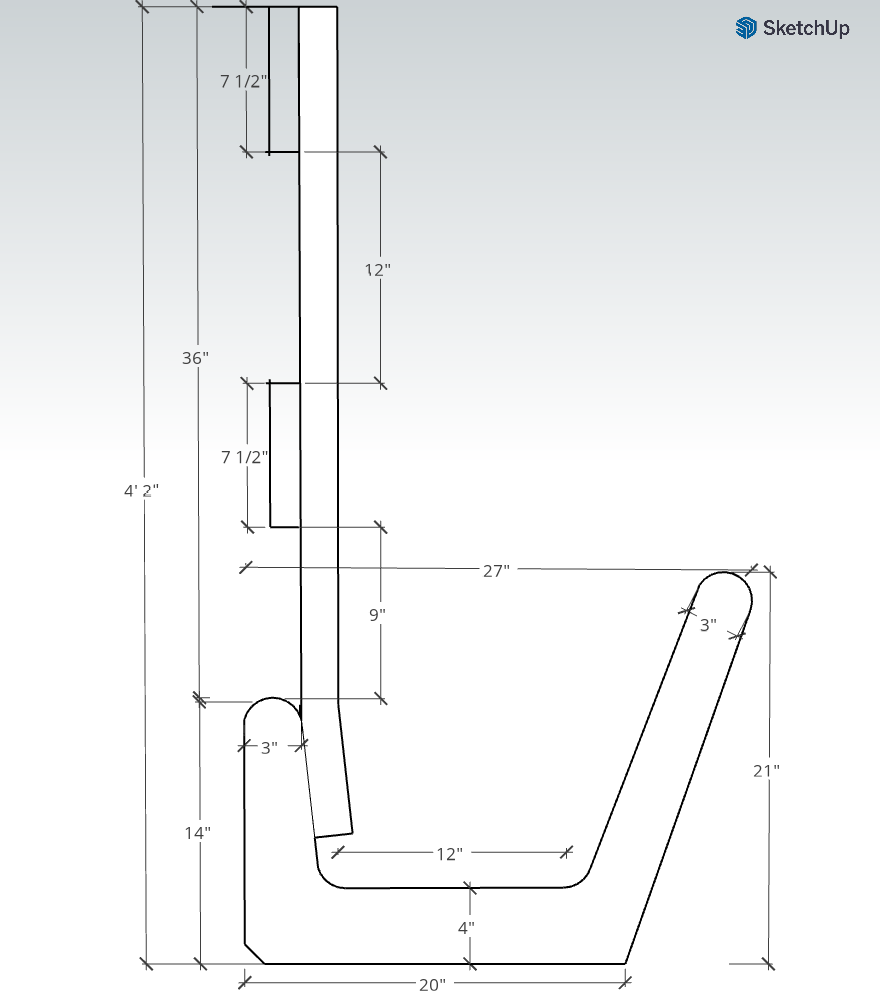

Our concrete Feed Bunks are designed to hold large capacity for the day’s ration, Slick finish and chamfered corners allow livestock to clean up feed. High back cuts down on feed waste, your animals will eat more and waste less. At the same time, the trough design keeps dirt and debris out of the feed

2. Saves Labor

Our concrete feed bunks are designed to be simple to fill and maintain. There’s no need to push the feed up thanks to their efficient design, and the bunks themselves require very little maintenance.

3. Easy Installation

Our concrete feedbunks are designed for easy assembly with a secure fit. Whether you’re installing them for the first time, replacing segments, or moving your feed bunks, you’ll save time and effort compared to other feeding systems.

4. Strong & Durable

When you’re setting up your farm or Feedlot for cattle or sheep, buying feeding equipment from L-con Industries is the smartest move. These stable and sturdy feed bunks will last you for years. We have feedbunks that were poured in the 1980s and still being used to this day. If one get backed into, an breaks, it’s easily replaced with one new 10′ section, unlike poured in place. Also if plans change you can easily rearrange your feeding pens however you may desire, and when you want to retire you can easily put these concrete feedbunks up for sale and get good value for them. High quality, High strength rebar reinforced concrete provides years of trouble free feeding!!

5. Easy to Clean

Because they’re made from high-quality concrete, they offer a smooth surface that makes each trough easy to clean. Combined with the reduced food waste and spoilage, you’ll be able to clean them quickly and thoroughly. If you decide to use the end plugs, they are easily removed with a convenient lifting anchor.